To avoid damage and injury, the mainsprings must be let down to relieve them

of their power before anything is done to the movement.

You must do this

even if the clock appears to have run down and stopped as a result. Some power

will still remain in the spring, and this will, at the very least, push the

wheels out of place.

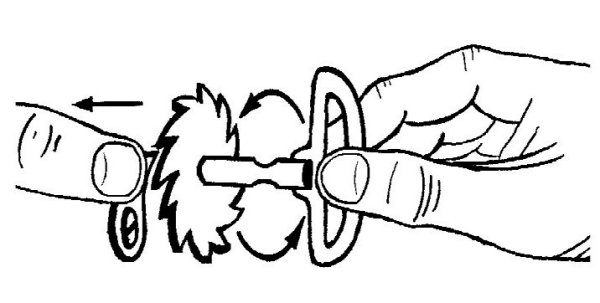

You may need an assistant for the next task. Select

a strong steel key that accurately fits the winding arbor. Holding the movement

in one hand, take up the tension of the spring with the key and gently ease the

spring loaded click away from the ratchet wheel.

Allow the key to rotate

about a quarter to half a turn and release the click. Ensure that the click has

engaged in the ratchet before releasing the key. Repeat the process until each

of the springs has been relieved of all its energy. Keys with wide wings have

less chance of slipping so never use carriage clock keys for this job.

Great care should be taken when carrying out this task as one slip can

destroy a finger as easily as a clock.

Letting down a mainspring using a key.

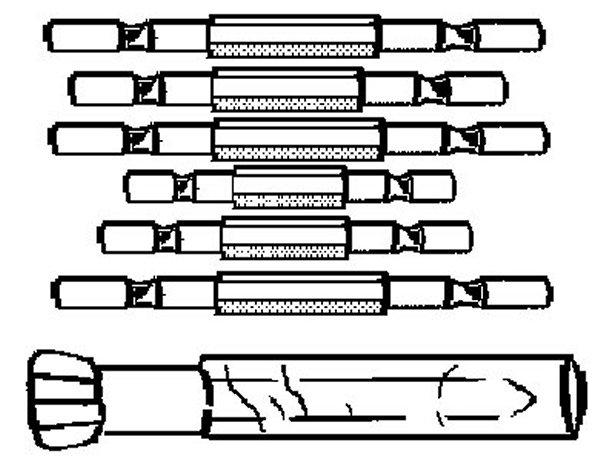

Let-down keys are purpose made tools to control the letting

down of springs. By having a key attached to a round handle, the speed of

rotation can be controlled by how tightly it is held.

A typical set of let down keys

Fusee clocks are best let

down when the clock has run down of its own accord, as the main ratchet is

inaccessible. The external ratchet only needs to be let down about 2-3 turns

when the clock is fully unwound. The short arbor used for setting up the fusee

is normally not suitable for letting down the whole spring. If a fusee clock is

not run down fully but will not tick, remove the pendulum and let it tick away

rapidly. If this fails, the escapement can be carefully removed and the escape

wheel allowed to spin round slowly. Control the speed with your fingers or an

elastic band wrapped around the arbor and slow down to its normal speed as any

striking time is approached.

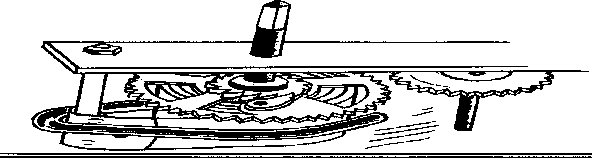

Movements with springs contained in barrels

are easily let down, and the barrel will then act like any other clock wheel.

Clocks with open mainsprings present the problem that, with nothing to contain

them, the springs get larger and larger as they are let down. They can become

quite unmanageable unless contained in the steel Mainspring Clamps manufactured for this purpose.

A open spring clock with a

mainspring clamp fitted.

Thick wire can be used, but this is

inclined to slip and makes re-assembly difficult when powerful springs are being

handled. An advantage to purpose made clamps is that the distance between the

centre of the loop and the centre of the coiled spring is maintained. This aids

assembly. Always treat springs held by clamps or wire with respect.

Repairing Your Own Clocks by Mervyn Passmore