The holes the pivots rotate in should be perfectly circular and fit the pivots.

Worn holes become oval and worn pivots become too small for their holes. This

becomes more critical the nearer the escape wheel it occurs and can cause

considerable loss of power. The cure is to fit new bushes to the holes.

There is a wide range of bushes to choose from, and it is best to

purchase an assortment of standard brass bushes in a compartmented box. If

any size gets used up first, you can buy replenishments. Before you consider

bushing a hole, overhaul the pivot.

From the assortment select the bush

with the nearest internal diameter hole to suit the pivot in question. Using an

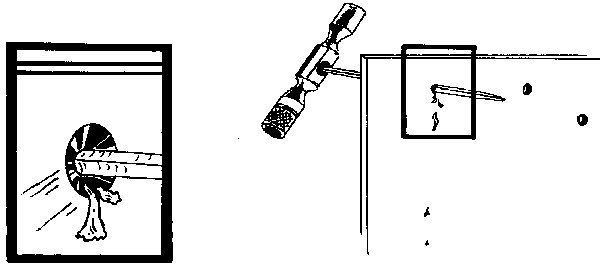

variety of cutting broaches , enlarge the hole until the bush almost

fits.

Using a tap wrench and broach.

Always broach from

the inside of the clock plate because the broaches are tapered and so the bush

will not be able to come out. There are many sizes of broach available and it is

not practical to purchase them all. You will find the outside diameters of many

of the brass bushes are the same. To start with you will need cutting broaches

that will make a hole those sizes, plus a few for the inner holes.

Always keep the broach at right angles to the plate. You can either fit

a wooden handle to the broach, or use a tap wrench which will give you more control over keeping it

straight. Stop when you have a hole almost as large as the outside of the bush.

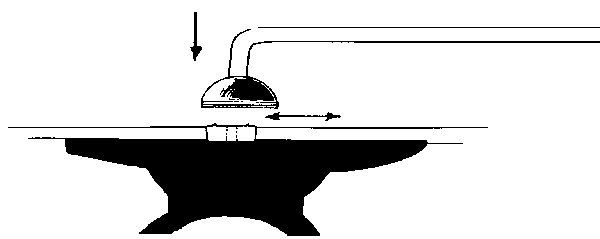

Place the clock plate on a flat stake or anvil and press the bush into the hole

as far as it will go.

Hammering the bush home with a

clockmaker's hammer.

Hammer it home with a clockmakers hammer . The riveting effect of the hammer will

spread and harden the bush. File away any surplus brass protruding from the

plate but avoid scratching the surface. The shape of a bulls foot file allows you to file without touching the

surface.

A bulls foot file will not damage the

surrounding area.

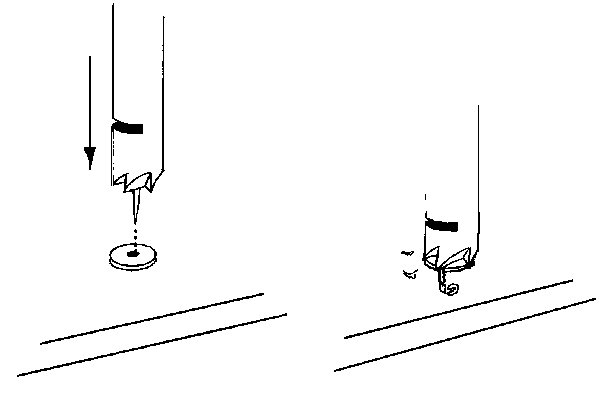

A counter-bore counter-bore is also excellent for removing

surplus bushing. Insert a pin into the hole in the counter-bore to help locate

it. This will ensure it rotates over the bush and does not slip off.

Using a burr remover to remove excess

bushing.

If an oil sink was there originally, then another is

easily made with an oil sink cutter.

Making the oil

sink.

Finally broach out the bush to suit the pivot using one of

a set of small broaches held in a pin vice or with its own handle. The finished

hole should not restrict the pivot in any way, and should allow enough freedom

for the arbor to move freely between the plates when the clock is turned upside

down.

Polishing (smoothing) broaches are available to bring the

inside of the pivot hple to a perfect finish.

Repeat this procedure for

all the badly worn holes. Some repairers feel that all holes should be re-bushed

when overhauling a worn clock. Generally, the larger the pivot, the less

critical the fit.

Repairing Your Own Clocks by Mervyn Passmore