Dismantling a clock requires little effort and a few minutes - re-assembly

the opposite.

It is most important you find somewhere where you can lay

out the pieces as you remove them that will not be disturbed. Experienced clock

repairers recognize each part for what it is but until you are familiar you will

need to make notes and sketches as you go along. Timepieces are by far the

simplest to work on, with only a few parts involved.

Striking movements

need careful scrutiny before being dismantled to observe their striking

sequence. Make the most of this examination and take as many notes as you feel

you need. In particular, the strike mechanism will normally have a 'warning' a

few minutes before it strikes. On the hour the lever that was raised to give the

warning drops, allowing the striking sequence to proceed. The number of strikes

is counted by a wheel appropriately notched known aptly as the count wheel, or a

toothed rack raised one tooth per strike. The drop of the rack is controlled by

the position of the hour wheel.

Be certain that you understand how the

mechanism works, as this is far better than trying to use memory alone.

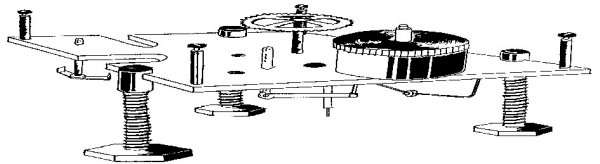

Before dismantling, it is essential that you let let down the power of the mainspring as

described earlier. Having done this, place the movement on the bench, supported

by two blocks of softwood or three of the Movement Clamps designed to hold movements while being worked

on.

A movement supported by movement

clamps

If using clamps, cover the plates with a thin piece of card

so that the jaws do not mark the brass.

Begin dismantling by removing the

fittings from the back-plate first, namely the count wheel, hammer, bell stand

etc. These are normally attached by tapered pins or screws. Handmade clocks

often had handmade screws which only fit the hole for which they were intended.

Make a note of these peculiarities as it can be very frustrating to find you are

left with a screw towards the end of assembly that should have been used at the

very beginning.

Having removed the fittings from the back-plate, the

front plate may now be stripped down including the ratchets and clicks, striking

rack, motion work etc. Failure to remove all these items will make the plates

difficult to separate without disturbing the relative positions of the wheels

and levers. A novice will need to observe them carefully whereas an experienced

repairer seldom has need to hesitate.

The plates will either be screwed

to the pillars that separate them, or held in position by tapered pins. With the

movement on its back, gently ease off the front plate. Striking movements will

be seen to have two distinct 'trains' of wheels, only connected by a lever that

triggers the striking train when the hands on the going train pass the hour and

half-hour position.

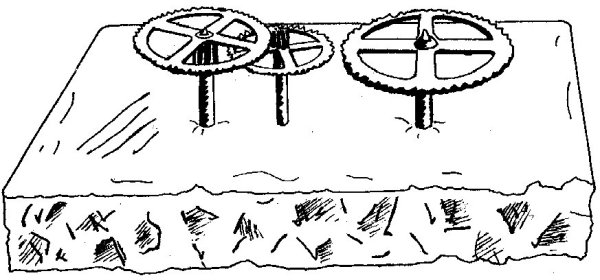

When removing the wheels from the train, place each one

the correct way up and in the right position in a piece of expanded

polystyrene.

Parts placed in some polystyrene, in

their relative positions.

You will see that as the wheels get

further from the springs or weights, they and their pinions become lighter and

more delicate. The wheels on the striking side often have pins set into

them.

Remove the lines from weight driven and chain driven movements. It

is wise to replace gut or clock rope etc. if it shows any signs of wear. Not

only is it easier to replace now than at any other time, but breakage can cause

damage to the mechanism and case. If chain needs to be replaced, make sure that

the one fitted is correct before you order another with the same dimensions.

Check that un-welded links have not stretched. For rope replacement, measure the

internal distance between the pulley flanges inside the clock, not the

weight pulley. The rope should be as wide as the pulleys will take without any

friction occurring as a result of the rope touching the sides. If it touches, it

may also ride up and off the spikes.

At this stage it is wise to examine

all the wheels, pinions, pivots and pallets for wear.

Repairing Your Own Clocks by Mervyn Passmore